Drying, dispersing and mixing equipment

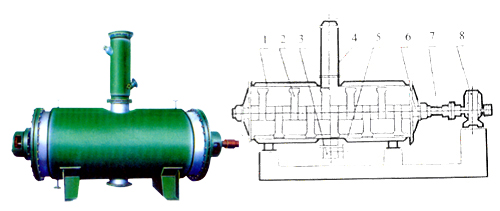

It has simple structure, convenient operation, long service life, stable and reliable performance, low steam consumption, strong application performance, and good product quality. It is especially suitable for drying paste materials that are not resistant to high temperature, flammable, and easy to oxidize under temperature regulation. The machine has been proved to be a good drying equipment after long-term use by users. Principle: The material to be dried is added in the middle of the upper part of the shell. Under the agitation of the rake teeth that rotate forward and backward, the material moves back and forth in the axial direction. The surface in contact with the inner wall of the shell is constantly updated. Uniform stirring and crushing of the crushing rods make the surface moisture of the material more beneficially discharged. The vaporized moisture is discharged from the vacuum pump outlet through the dry dust collector, wet dust collector, and condenser. Structure: The main components of the vacuum rake dryer

1. Shell 2. Harrow teeth 3. Discharge device 4. Feeding device 5. Crushing rod

6. Sealing device 7. Stirring shaft 8. Transmission device

Applicable materials

Mud-like, high-paste-like materials below 100 mesh, various pigments, mud-like materials, filter and centrifuge filter and soda ash detergent,

Alkali starch, dyes, pigments, clay ash, etc. Clay, etc. Cement, etc.

Apply under appropriate conditions

Material below 100 mesh, solution, synthetic fiber, crystal, vacuum liquid, emulsion, sweet potato chips, ore, etc. Suspension

Model and technical characteristics

| Main parameter model | Nominal volume | Heat transfer area | One-time loading | Work pressure | Operating temperature | Spindle speed | Material | Weight | Motor Power | Dimensions (L×W×H) | |

| Inside the cylinder | In the jacket | ||||||||||

| XPG0.5 | 0.5 | 1.86 | 0.2 | 0.021 | 0.686 | 435 | 15-20 | Note: 3 | |||

| Supplement: 5.5 | |||||||||||

| XPG1 | 1 | 6 | 0.75 | 0.021 | 0.686 | 435 | 9 | A3 | 3400 | 5.5 | 3700×945×3270 |

| 1Cr18Ni9Ti | 3300 | ||||||||||

| XPG2 | 2 | 8 | 1.2 | 0.021 | 0.588 | 425 | 9 | A3 | 4900 | 11 | 4570×1130×3455 |

| 1Cr18Ni9Ti | 4800 | ||||||||||

| XPG3 | 3 | 11.5 | 11.5 | 1.021 | 0.588 | 425 | 9 | A3 | 6400 | 15 | 6076×1130×2980 |

| 1Cr18Ni9Ti | 6300 | ||||||||||